Product Life Cycle ( PLC)

In our busy lives, we use thousands of products on everyday basis. Have you ever wondered about product life cycle? Like human being, product too have their life cycle phases. PLC defines the complete cycle of product from its launch in market to elimination from the market. PLC is one of the important concepts for companies to decide/approve company products portfolio expansion, reviewing the scope of product or to verify products success in market, etc.

The general phases in product life cycles are namely -

1. Introduction

2. Growth

3. Maturity

4. Decline

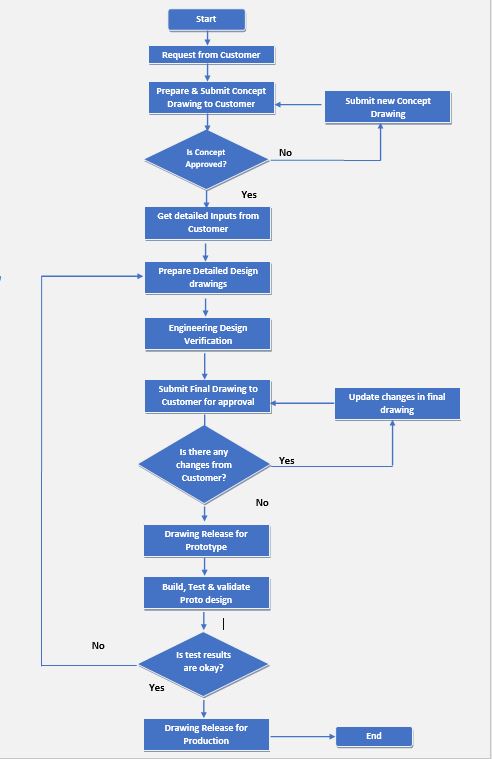

Above are the typical life phases of the product but it is not guaranteed that every product will attend all the phases. The performance of product is depends upon its need, demand and other factors too play a vital role in product life cycle and they are seen from a market point of view but there are lot more activities happens before product launched in market, as an engineer, we should aware about those behind the scenes. All the things happens behind the Introduction stage are falls in stage called as Pre-Introduction Phase.

So, for engineering perspective, typical product life cycle consists of -

So, for engineering perspective, typical product life cycle consists of -

1. Pre-Introduction

2. Introduction

3. Growth

4. Maturity

5. Decline