Engineering Design Process

We all studied general engineering design process,that consists of below steps -

1 - Find Problem or Need

2 - Gather required information

3 - Find all possible alternative solutions

4 - Select Best solution among them

5 - Build the solution (Prototype)

6 - Test and evaluate solution

7 - If result is satisfactory then release solution, if not repeat steps from 1 to 6.

But in actual engineering design process,there many steps involved and every organisation have their own engineering design process, almost similar to each other with the foundation of general engineering design process.

Here, I'm writing about engineering design process I understood from my experience.

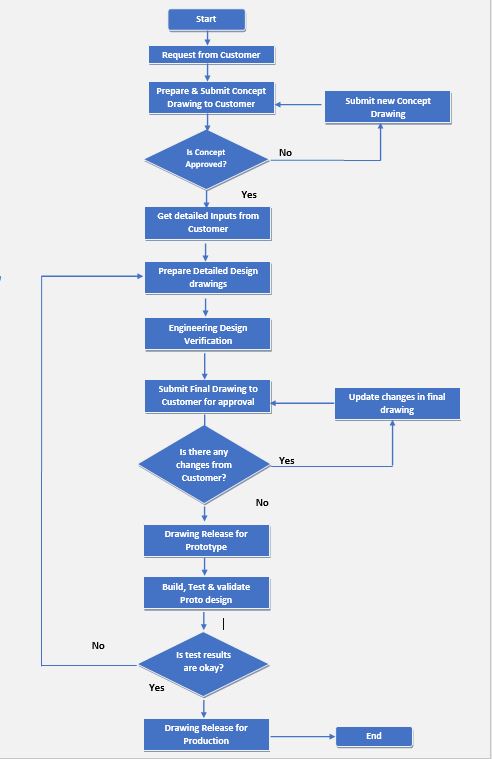

Flow Chart -1

Explanation -

1. As shown in flow chart, firstly customer approaches multiple organizations by providing some requirements of product needed for their vehicle. Let's say, OEM requires tires for their new vehicle, so OEM will approach different organizations having expertise in tire manufacturing.

2. After receiving the request and basic requirements, tire manufacturer starts engineering activities and create concept drawing, CAD model of new tire and submit it to OEM for review.

3. OEM reviews the concept design. If design approved, they provide detailed tire requirements of vehicle to selected tire manufacturing company. If design not approved, tire manufacturing company still has chance to submit another concept design unless and until OEM did not approve any other tire manufacturers concept design.

4. Considering concept design approved scenario we will understand next steps. After receiving detailed requirements tire manufacturer starts working on detail drawing. As product (tire) manufacturer, they are responsible for all engineering design calculation & validation, but OEM also takes part in this.

5. Now, after engineering design validation, tier manufacturer submits final detailed prototype design drawings to OEM for review.

6. If any design changes received, that changes need to accommodate and re-submit the updated Prototype design drawings to OEM. If no design changes received from OEM, tire manufacturers are ready to release Prototype drawings and prototype build is carried out.

7.After prototype build, there are tested in engineering labs as well as actual field environment where final vehicle will be in operation.

8. If results vary from requirements all the activities from detail prototype drawing to engineering lab and field test will be carried out again until the results meet the requirements. If both the engineering lab and actual field results meets the desired vehicle requirements, all prototype drawings are released for production.

No comments:

Post a Comment